As promised in the last post, I have a story to tell regarding chassis 288 from Tom Walkinshaw Racing, it was put together by Kerry Morse a few years back when we ran SportsCarPros together. Typical of Kerry’s work, it is too good to molder in the archives of a dormant website. Why now? Well the car was one of the stars of the Retromobile on the Hall & Hall stand, more on that topic later.

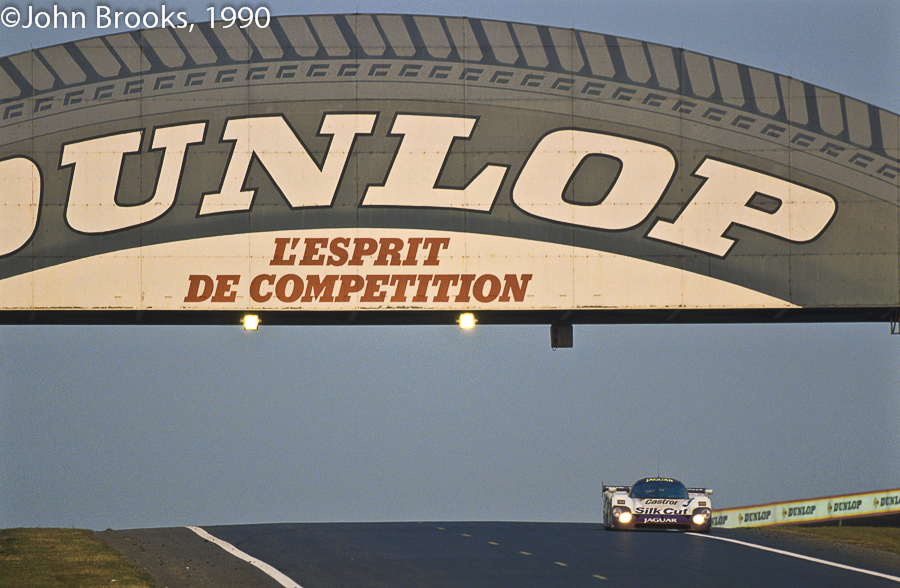

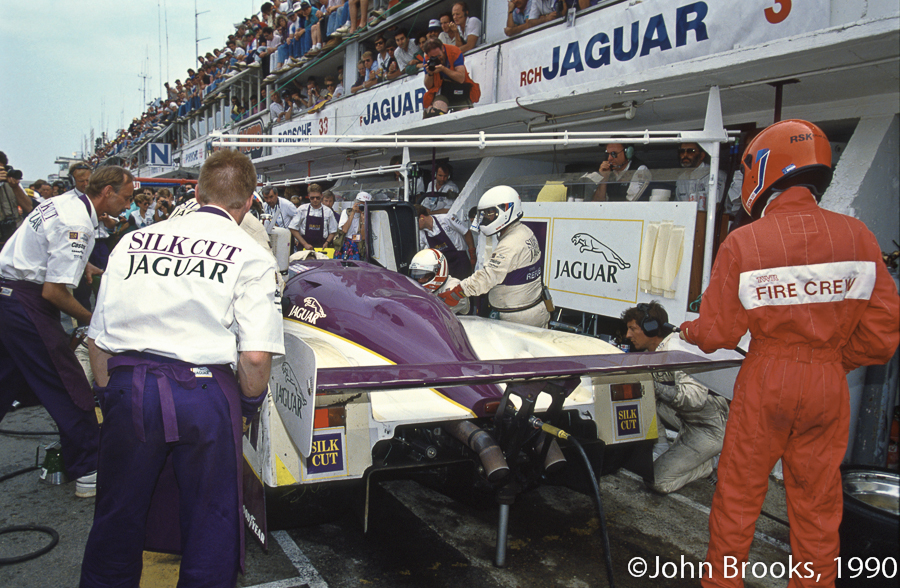

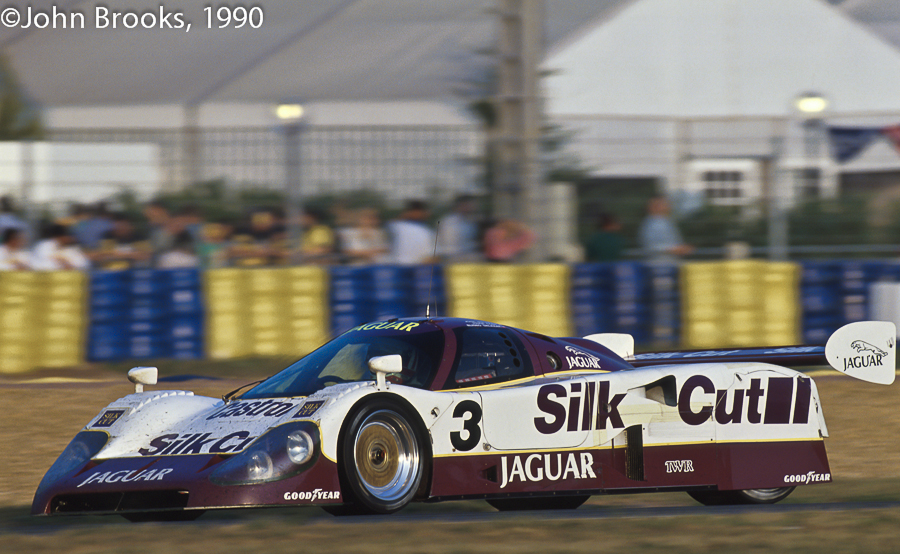

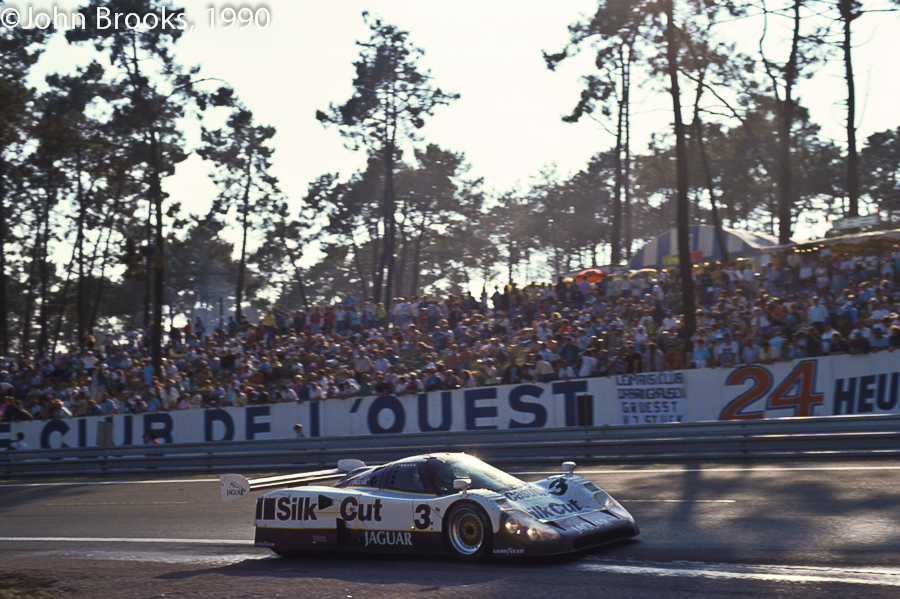

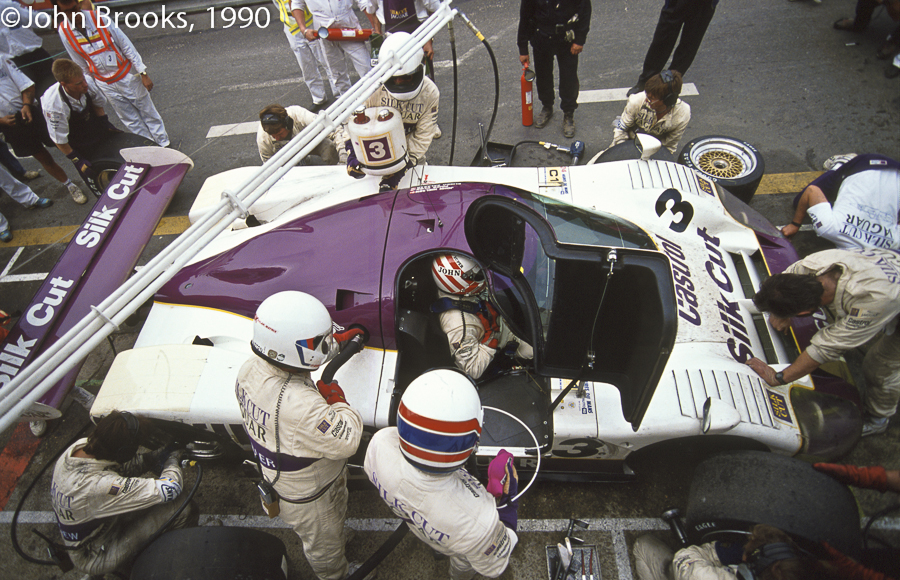

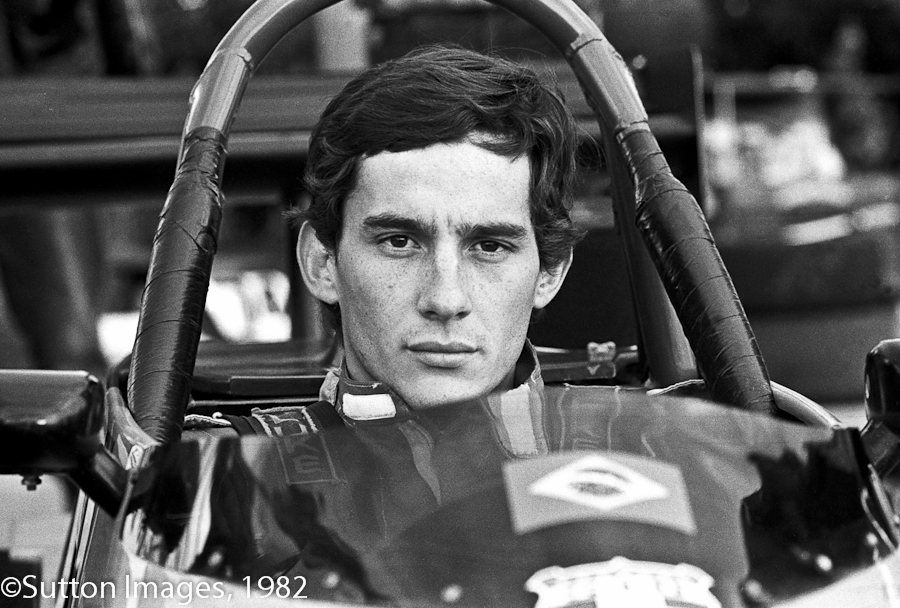

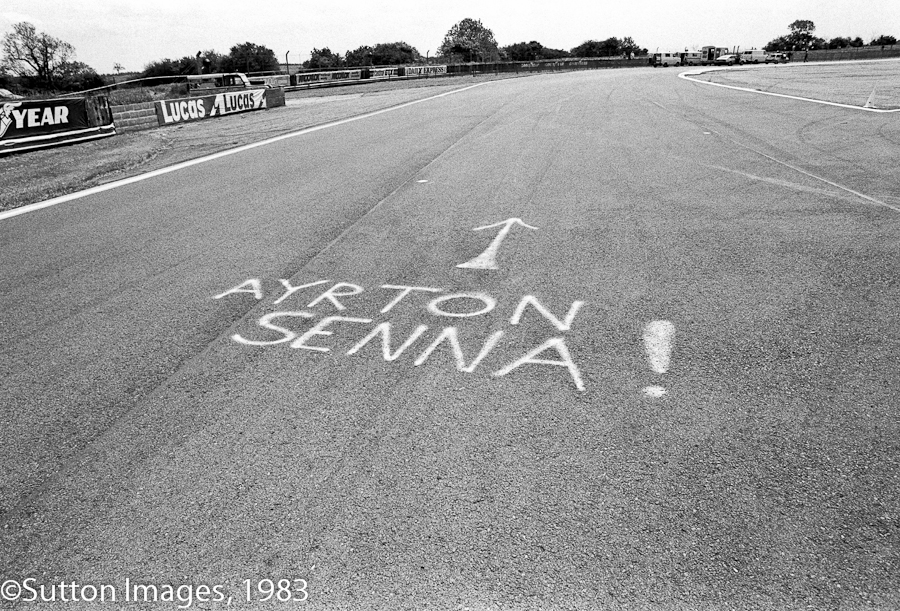

Kerry and I both have a personal connection to the story and 288. I was shooting with Keith and Mark Sutton at the time and had introduced them to Castrol, which led to work with Jaguar and Silk Cut, so we were busy at Le Mans in 1990. If you have five minutes visit their archive HERE you will soon lose an hour or two with all the amazing photography. It is with their permission that I use these images. Kerry’s connection is that he arranged the purchase of this car for a client a few years back. Plus we both hold Tony Dowe in high regard, this is really his tale……………

John Brooks, February 2013

There are winners and there are WINNERS. Tony Dowe obviously belongs to that

second group of selected individuals. John Brooks and I want to thank Tony for all his efforts over the years of getting great performances from the teams he has been involved with. He makes our job a lot more interesting. What was it that mean old Ron Dennis once said to a gathered group of hacks. I think it was something along the lines of “ We make the history, you only report it”. Tony Dowe has made and continues to make history.

Kerry Morse, February 2005

What it takes… Tony Dowe on winning at Le Mans with Jaguar

I worked for Tom Walkinshaw Racing from 1987 until 1998 as Managing Director of TWR USA. During this period one of my “duties” was to supply a couple of cars as part of the massive TWR/Jaguar effort at Le Mans. Unfortunately it was always made clear, never by Tom Walkinshaw of course, that the “American” cars were only there to support the real effort that was run from Kiddlington. Obviously this became a bit “second hand” and so after being the supporting act in 1988 and 1989 I gave some serious thought as to how to:

a) Win the race

b) Circumvent the restrictions placed on my U.S. team because of the supporting role we were expected to play.

The Rules of the Game

Let me say here that you should only undertake such an action if you’re sure that you can carry it off! Because to achieve anything less than the win is to open one’s self up for a very long period looking for a new job! Of course, if you win, then most of your sins are forgiven!

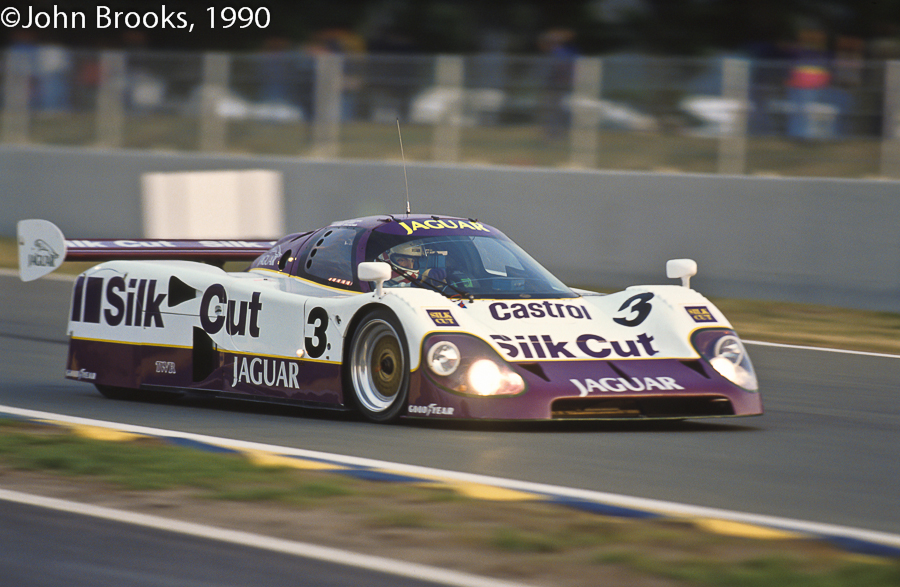

I always felt that TWR USA were a better race team than the UK team for no other reason than by the time Le Mans came around we had done a 24 hour race, a 12 hour race and a couple of sprint races. The Group “C” team had probably only done a single race and some testing. We were very sharp by 1990. We had finished 1st and 2nd at the Daytona 24 Hours that year, 1990, and had had such a better team we had each car race each other the whole 24 hours. It was a fantastic race.

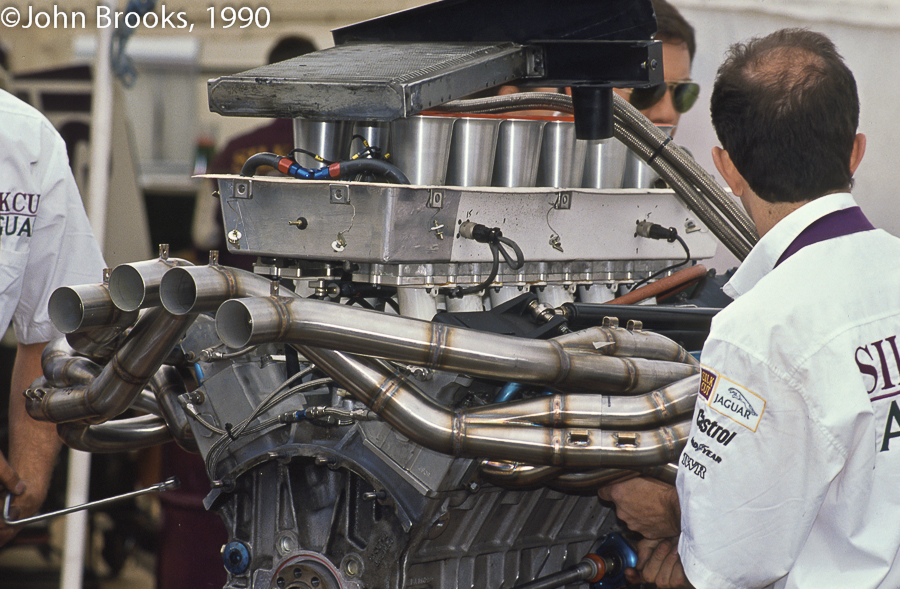

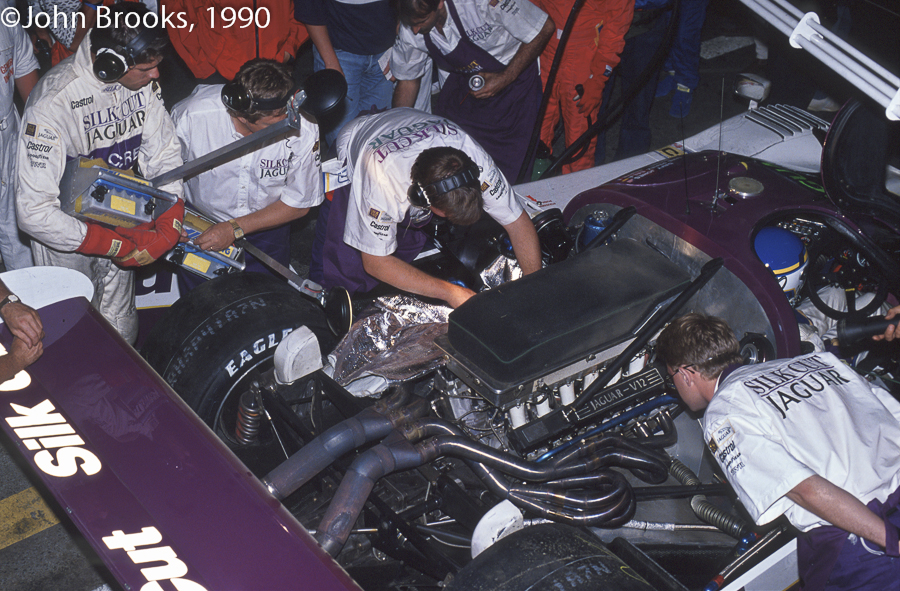

TWR USA also had a couple of very good engineers, Ian Reed, recently head of development at Penske, and Dave Benbow, recently with Prodrive. Ian and Dave were very good in their respective areas. Both were and are lateral thinkers and complemented each other very well. Ian was, as now, very good with the suspension and we were running dampers, for example, that were much ahead of the ones used by the UK team. We had briefly used a pair on the rear of the car in 1989 when Davy Jones led the race in the early stages. The biggest problem that had to be overcome was that, along with most of the other team cars, we were only allowed a single engine for both practice and the race. The only team car that had a qualifying engine was the one that was lead by Martin Brundle.

As we were now running the V-6 turbo cars on a regular basis in the IMSA series, we were able to take one of our V-12 cars out of the mix and prepare it with a lot of love and care. We used chassis 288, which had won our first ever IMSA race in the USA back at the 1988 Daytona 24 Hours. The lead mechanic was Winston Bush, still in Indianapolis, and he did a super job of building a car to the exact same specification as the UK cars!

Dowe Chemicals

Now we get to the interesting bit!

The week before we had to leave for Le Mans we were racing at Lime Rock Park. Super place and made better when John Nielsen and Price Cobb won with a turbo car for the first time, exactly a year after we had début of the first TWR Jaguar turbo. There to see the car win was the head of TWR engines, Allen Scott. Allen is now back in New Zealand enjoying his retirement and rallying a Mazda. After the race we had a super night at a very nice local restaurant run by an English guy called Terry. Lots of drink, etc. After the meal I took Allen to one side and asked him why “my” car could not have a qualifying engine for Le Mans? Allen, now very “mellow” told me to use common sense, “It’s just not going to happen”.

I then asked what would happen if we had a mis-fire at the end of qualifying that

could not be found. Allen said, “obviously there would be spare engines for such

an eventuality.” Allen was booked on a flight from Kennedy the next morning back

to the UK. I then played the trump card. I produced an envelope from inside my

jacket and told Allen that inside was a ticket for the next morning’s Concorde flight

to London. It was his if he found a problem with our engine after Le Mans qualifying. After a moment of hesitation Allen looked around and then took the envelope and put it in his jacket pocket. The game was on! Only Ian Reed was aware of what I was planning. And he was like a kid when I told him the bait had been taken. The now finished “vanilla” 288 chassis was sent to the UK for painting and, I suppose inspection to see that we had built the car to the decreed spec.

We then set about putting together a “care package” of our IMSA “goodies” for fitting when we got to Le Mans. We had different roll bars, front and rear. Different shock absorbers front and rear. But the biggest item were some very special one piece (Billet) brake calipers that Ian had designed and we had built here in Atlanta. They were made to accept a much thicker brake pad than standard, Performance Friction made the pads for us. So now we could also go further than the UK cousins without a pad change. We had also had “Rabbit” (A legendary fabricator who still lives in the Georgia mountains) build us some really trick pad changing tools. The gearbox was built with a limited slip differential. This was quite different from the UK cars because the thinking was that with a “spool” fitted if a drive shaft failed you could get back to the pits! Well, unbeknown to the guys in England, we had Kenny Hill of Metalore (they now make most of the F1 world’s hubs/drive shafts and axles) make us some super strong F1 type drive shafts.

Can you hear me Major Tom ?

One further item that would prove very useful was the use of the American radios.

Every year we had gone to Le Mans the circuit length meant that the European radios supplied by a guy called “Crackly Ken”. They usually gave up when the cars left the pits! The last thing that we had changed at TWR USA was the rear wing. With the additions of the chicanes along the Mulsanne straight, Le Mans was now the same aero level as Daytona, things were just going our way.

Lock, stock and two smoking barrels…

So now the fun started.

We started practice with “just a few bits” changed, radios etc, so there was not much notice taken of what we were doing. There was a bit more interest when the brakes went on and the roll bars were changed, but at the early morning meetings the comments were mainly directed towards us in the manner of “So what silly things have the you Americans changed now?”

Roger Silman, the UK Team Manager, was more concerned with why Jan Lammers could not match Brundle’s practice times. He did not like drivers, or anyone else for that matter, to think for themselves about how the race should be run. I’m sure that Tom had some idea of what we were doing as he was a regular visitor to IMSA races and was aware of our development items, but he never said anything to me about what we were up to.

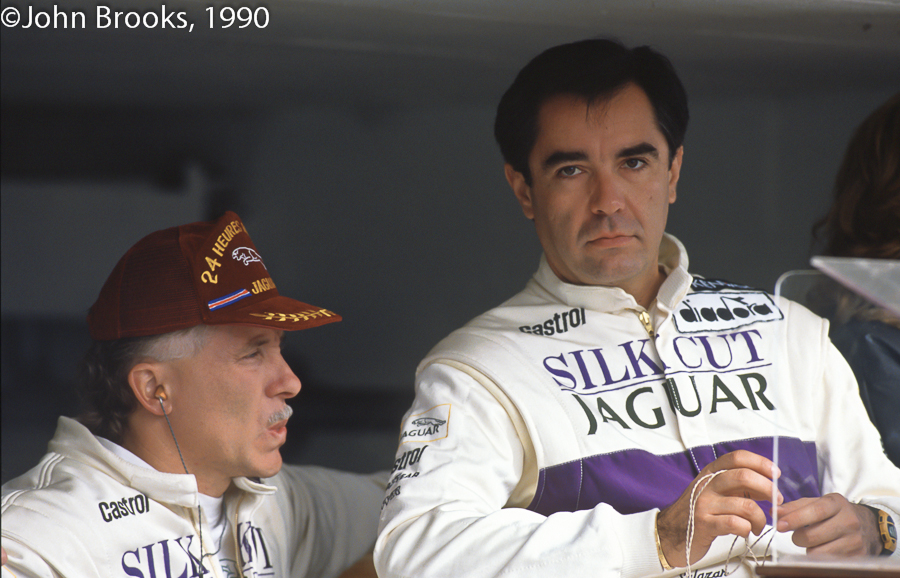

Our driver lineup was pretty good, “Big” John Nielsen, Price Cobb and Eliseo Salazar. Obviously John and Price knew what we had fitted and were very happy because it brought the car to the same specification as they had been used to racing. Unfortunately after the end of practice, guess what? Allan Scott found the “mis-fire” and we had to change engines! Another hurdle crossed, because if Allan had gone back on the “deal” then the whole plan would have probably sunk out of sight!

Friday’s pre race preparation brought to light another small problem. The gearbox “dog rings” were being used by one of the drivers in a way that was too heavy on the gear changes. As we had lots of experience of John and Price it was obvious that Eliseo was the problem. I went and found Julian Randles, then of Spice Engineering, who Eliseo drove for sometimes in IMSA and had a “discussion” about his experiences with Eliseo and his use of the gearbox. Julian confirmed that Eliseo’s style of gear changing was quite heavy on the dog rings. I had a long day of thinking about how to deal with this problem, and it was a problem, because with a dog box we were going to probably lose 3rd and maybe 4th gear if history was any guide.

I went to dinner with Tom, his lady Martine, and a guy from Jaguar who I honestly can’t remember who he was. During dinner I told Tom of my concerns and suggested that it might be a good strategy if I kept Eliseo out of the car for as long as possible in order to keep a seat free should one of the other “favourite “drivers had a problem. Tom agreed and so at our race morning briefing I told the drivers that we were going to use “Big John” and Price through the evening and night until Sunday morning, when Eliseo would be “fresh” for the remainder of the race.

Sex Pistols and the holiday on the grid

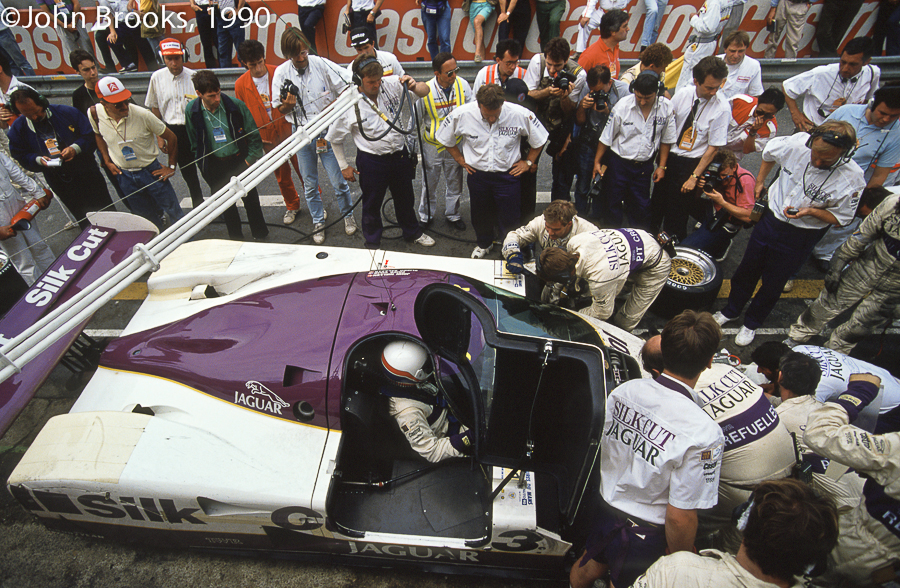

Race day: Just as we parked the car on the “dummy” grid, JJ found a small fuel leak from one of the fuel pump unions… Now, as it is today, there can be no work done on the car on the dummy grid. So what were we to do?

Well one of our XJR-12 design features was that the whole fuel system, pumps, filters etc, were mounted in the left-hand side pod on quick release clips. So it would only take moments to change them. The problem was how to make the change with the whole ACO “police” walking up and down the grid!

Fortunately we had made some very nice mock leather “pouches” to protect the spare pump assemblies in. While the whole team posed in front of the car with, what else, the Hawaiian Tropic girls, JJ slid inside and changed the leaking pump assembly for a new one! Honestly! I think that in another life JJ would have made a great David Copperfield.

The numbers added up for a very Goodyear…

The race its-self was quite easy.

One of the big race advantages we had was that having run at Daytona we knew that the “standard” 480 compound rear Goodyear tires would not double stint on the Jaguars at Le Mans. So back in February at Daytona we had run a much harder 600 compound tire during the heat of the day. When we arrived at Le Mans I found that Goodyear Europe had no 600 compound tires available! Our tire guy for this event was the great American Airlines guy, Kenny Szymanski. I called back to the States and had 10 sets of 600 compound tires shipped in without anyone knowing, thanks to Ken Moore of Rapid Movements. Kenny S. did his bit by removing the tire coding from each tire and hiding the tires inside the old pit tunnels.

When we started double stinting the tires and beating the UK team “hands down” in the pits, I had a very “uptight” meeting with Tom as to what was going on!!! I had to come clean as to what was going on and we were forced into giving some of our rear tires to Brundle’s car. All of this while trying to run the race! One of the other “fun” bits happened around 10:00 PM. A car had caught fire at the Porsche curves and the ACO had put out the Safety Car. John Nielsen had just been in for fuel a couple of laps earlier and he called in and told me it would take a bit of time to clean up. Just like we would over here. Good US radios at work. I called him straight into the pits to top off the fuel, as you would! Boy, did that move unleash a load of trouble. I had Tom right in my face about giving up track position. Obviously the UK team cars continued running around under a caution flag while we topped off the car, so they then had to pit under a green when we went back to racing! About an hour later we went into the lead after everyone else had had to pit for fuel, etc under a green. This was a lead we never gave up.

Big Bad John

The next bit of drama was that Price was slowly dehydrating, remember, these cars had no power steering, little ventilation and no drink bottles, and over 5000 lbs. of downforce in those days. So during the middle of the night we had to ask “Big John” to triple stint (!!) while Price recovered. A star then, still a star now. Then the Brundle car, which had been fighting a slow water leak, finally called it a day. Tom came and asked me if I thought the car would be able to last until the finish (!) You can imagine my reply.

TW took Eliseo off our team and told him he was not going to drive and he was putting Brundle in instead. You can imagine how heartbroken Eliseo was with this decision. So around 8:00 am Brundle got in the car.

The Mechanics of the Isle of Sodor

The only thing we now had to deal with was the 3rd gear had decided it had enough of the chicanes and gave up. This meant that the drivers had to change from 2nd to 4th, not a great problem, but enough to get some very dirty looks from TW! The final drama was a couple of stops from the end we had a scheduled brake pad change and JJ (John Jackson, our regular chief mechanic, ex Williams F1) found a couple of caliper pistons leaking! So we had to change one of our mega expensive calipers. Now they were a bit tight on the studs, so Pete “Hodge” (Peter Hodgkinson, a New Zealander and now the new car build manager at BAR) took a very big hammer to our beautiful machined caliper to quickly remove it! Job done and not too much time lost.

Then politics started to take over. The “Management” wanted to have the UK team suddenly involved so they would look part of the effort. No way.

The Day of the Jackal

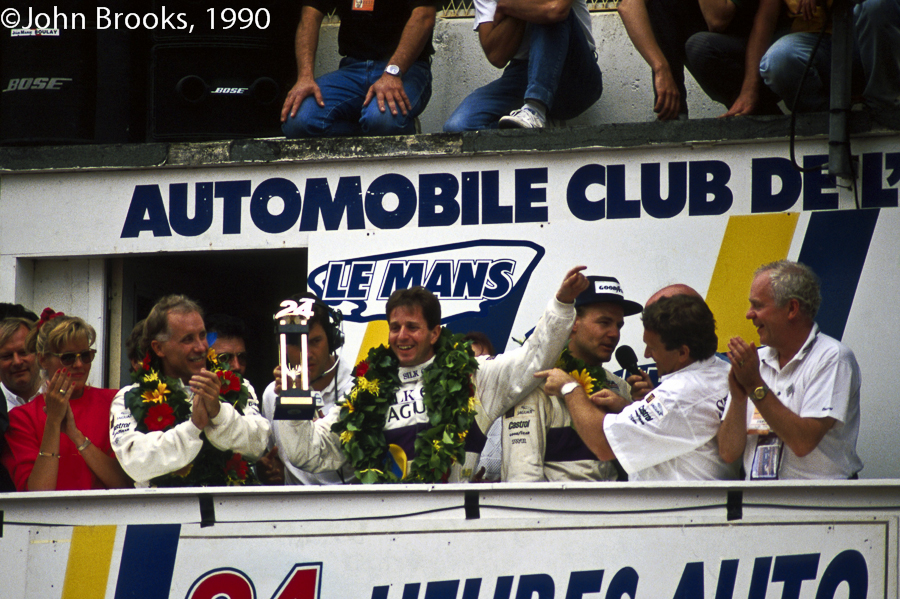

So we won. Very satisfying.

Mike Dale, then MD of Jaguar North America and a true racer, had supported us all the way and was terrific as the laps wound down. Our car was the only chassis that had won both the 24 hours of Daytona and Le Mans as far as I’m aware of. Now it was lots of celebrating. I remember taking TW back to the airport and he told me I had “done good” I then had to find my way back to the chateau where we were staying. Now that was a trip. I was so tired, and a bit the worse for Champagne. I can’t remember how many times I went off the road. And all the while driving Tom’s personal Jaguar.

The next morning we went back to the circuit to see the car and it was very emotional for us when we untapped the engine cover and lifted the rear deck off. Never lifted it in the whole race. A couple of weeks later the whole team who had been at Le Mans went to New Jersey and had dinner with Mike Dale and Bob Burden, another super Jaguar person, in a small restaurant a few miles from the Jaguar Headquarters. Very nice.

There are very few people that knew of the lengths that we had all gone to get this result, so this is the first time I’ve told the whole story. Thanks to all of the “villains” that took part, it is something to tell the kids when you grow up. I hope that we will be forgiven, but only ever do this if you are sure your going to win.

Tony Dowe, February 2005